Do you run a small or large scale nursery or plant potting or potting-up operation? Would you like to TRIPLE your potting production and greatly reduce your labour costs? In the laborious task of potting, there are several issues with manual potting. Manual Potting can be a slow, labour intensive, not ergonomic, expensive and possibly a daunting job.

Do you run a small or large scale nursery or plant potting or potting-up operation? Would you like to TRIPLE your potting production and greatly reduce your labour costs? In the laborious task of potting, there are several issues with manual potting. Manual Potting can be a slow, labour intensive, not ergonomic, expensive and possibly a daunting job.

What is a Comet Potting Machine?

What is a Comet Potting Machine? Brief history of Comet Potting Machine

Brief history of Comet Potting Machine (to maximise potting efficiency):

(to maximise potting efficiency):

Your COMET makes potting easier and less physically stressful. Easier on the back, arms and hands.

The picture allows potting at a comfortable waist height without stress on the operators back and arms.

2. Staff are now never daunted by large potting jobs again!

2. Staff are now never daunted by large potting jobs again!Your COMET's easy, comfortable operation makes light work of even the biggest potting projects. Some COMET owners say that their staff now “enjoy potting and even compete to beat production records” (link to testimonial)

COMET enable you to handle large potting jobs with ease .

The generous sized standard 1 metre cubic hopper (and extra big optional 2 metre hopper) mean you can pot a large number of plants before needing to refill the machine with potting mix. This means you spend more time actually getting plants potted in a day.

The picture shows filling the Comet hopper with potting mix using a skid loader (note the heavy duty grille to exclude logs, bricks and careless operators).

Note: (1) While getting spare parts for some imported machines can be costly and time consuming, C-Mac can supply you with affordable locally made spare parts fast.

(2) With constant running, overtime the only major parts that need to be replaced from time to time are the elevator chains, sprockets and rollers. Our current COMET owners find chains last up to two years depending on the composition of the potting mix used. Chains, sprockets and rollers are easily replaced.

No set up time - no training required to use the machine

No set up time - no training required to use the machine

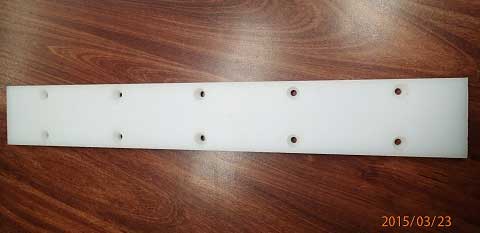

Spare Parts for Steel COMET

Spare Parts for Poly COMET

To minimise your machine downtime,

Photo Gallery

Filling Pots

Filling PotsPotting mix from the polyethylene hopper is picked up by a series of galvanised trays that are elevated by the operation of a heavy duty motor driving the dual sprockets fitted to the drive shafts.

Fertilizer dibblers are available for direct application of a measured amount of fertilizer into the pot or bag, operated by a foot pedal (See below).

Pot directly into containers from 50 mm up to large pots and plant bags.

Pot any size tube, pot or bag quickly, easily and without root damage.

Pot any size tube, pot or bag quickly, easily and without root damage.

Being able to adjust the flow rate of the potting mix is helpful with filling the smallest tube right up to the largest bag.

Centre each plant and secure it quickly and easily without damaging the roots.

No wasted setup time means you get right onto the job of potting immediately.

Whether you've got a handful of plants to pot or thousands, the COMET is always ready to go.

Even when you're changing from one pot size to another, there's no time consuming changes that need to be made - just adjust the flow of the potting mix with the turn of a knob.

In fact, the COMET is so flexible, two workers can work side by side, potting different size pots at different rates.

In fact, the COMET is so flexible, two workers can work side by side, potting different size pots at different rates.

COMET keeps your potting area clean, organised and safe.

Your COMET recycles the potting mix, keeping the surrounding floor clean and safe for workers. No potting media wasted or contaminated. Compact, safe design fits neatly into most potting areas.

Picture: Filling medium sized pot VS Filling medium sized bags with ease

Fill large pots quickly and easily with your COMET.

Fill large pots quickly and easily with your COMET.

Just add the “large pot filling chute” to direct the potting mix flow into your large pots. The large pot chute is foot pedal operated and moves under the soil flow and directs the potting mix into the large pot.

On release of the foot actuator, the chute moves away from the COMET allowing the continual flow of potting mix to be returned to the hopper.

.jpg?width=192&name=Stands_for_filling_large_pots_(note_the_clean_work_area).jpg) Large pots are much easier to handle and fill using the adjustable large pot stands - no more back breaking work holding large pots while being filled.

Large pots are much easier to handle and fill using the adjustable large pot stands - no more back breaking work holding large pots while being filled.

The picture to the right shows the “large pot stands” and the foot pedal actuator rods that operate the mix chute to position it under the potting mix outlet, to then direct the potting mix into the pot.

Right-hand side picture - Stands for filling large pots (note the clean work area).

Pictures of "Chute activated to direct mix to large pots" vs "Filling chute"OFF".

Increase plant growth consistency with COMET fertiliser dibblers (an affordable optional extra) to stop profit wastage because of uneven plant growth.

Increase plant growth consistency with COMET fertiliser dibblers (an affordable optional extra) to stop profit wastage because of uneven plant growth.

For maximum profits, nurseries must fertilise every plant with the same measured dose of fertiliser. Inconsistent growth due to inaccurate fertilisation is a costly problem.

COMET's optional fertiliser dibbler makes adding the exact amount of fertiliser quick and easy every time.

Picture of COMET fertiliser container, feed pipe, and variable amount controller. This image also shows the potting mix outlet chute with the mix feed rate control knob just above the chute.

The variable controller sets the correct amount of fertiliser to be added to each pot.

When the fertiliser pedal is activated (hand or foot), the electronic actuator opens the slide and releases the set dose of fertiliser into the feed pipe which is directed into the pot being filled. See pcitures below.

Dibbler actuator rod and slide

Easy foot pedal activation of fertiliser dibbler for pots and bags

Hand operation of fertiliser activator for large pots.

The performance of a COMET POTTING MACHINE cannot be stated in pots per hour. There is no conveyor or any mechanical apparatus that delivers a set number of pots per hour.

The performance of a COMET POTTING MACHINE cannot be stated in pots per hour. There is no conveyor or any mechanical apparatus that delivers a set number of pots per hour.

Like any other good piece of nursery equipment, the COMET is a helpful TOOL which is only as effective as the person operating it.

Good team work is essential as the operator must be kept in constant supply of plants to be potted, empty pots and potting mix. Then, the handling of the potted plants is also a major part of the potting operation. You can pot thousands of plants per hour but they must be transported efficiently from the potting area to the growing area (Nursery self tracking trailers or nursery barrows could help you with the plant transport)

Picture of Filled pots in nursery growing area

The only numbers that can truthfully be stated are numbers of pots per hour placed in the growing area, and as with all potting procedures. This is a team effort. The team may consist of one person or five persons. Handling of the crop is a larger part of the job than the actual potting of the plant in the container.

The only way to obtain a true comparison is to quote some examples of actual performances from nurseries using the COMET potting machine.

| Location | Number of Staff | Container | Quantity |

| Nursery in Nth Q’ld | 5 | 50mm tubes | 2,500/hour |

| Another Q’ld nursery | 3 | 125mm pots | 7,200/day |

| Citrus nursery | N/A | 200mm bags | 7,000/day |

| Wholesale nursery in NSW | 6 | 150mm pots | 10-11,000/day |

| Nursery from South Aust. | 6 | 300mm pots | 6,000/day |

Another common statement is "I don't usually count numbers but we have doubled our output with much less stress."

One well known nurseryman in South Australia said when he first used his new machine "It's fantastic! We used to pot a thousand tubes a day and now we pot a thousand an hour!"

And there are many more examples.

The performance of the potting team depends on the co-operation of the members and the availability and wise implementation of good materials handling equipment and techniques. It is generally accepted that although the concept is different, the total days production is similar whether a COMET is used or a more fully mechanised imported machinery is used.

A COMET is well worth considering because:

It Just received our potting machine on Friday and set up today (Sunday) and wow!!!! Are we pleased!

Potted 600 perennials each in the first hour! Usually do 100 each.

Many thanks for your great service. Very pleased with the quality and heavy duty nature of this machine. I'm sure we'll get many years use from it..... will outlast me I'm sure.. The staff member helping me today was also rapped..

Many Thanks

Ken Batchelor

Hook Bush Nursery

22 November 2009

It is the perfect machine for every nursery. Other machines are far too complex requiring too many people to operate them.

We just found many benefits with the Comet, labour saving, it stands just at the right height, less stressful on the staff, anyone can operate it and anyone can fix it.

Maarten de Lagt - Road and Traffic Authority - Wooloongong NSW

I am more than happy with our Comet, it allows us to work at our own pace and saves our workers' backs. We can pot from one size to another which other more expensive potting machines do not allow.

Currently we are potting 30,000 plants per year in 8", 10" and 12", with the majority being 8". The machine was purchased on 2nd October 1993 and has been doing a great job for us ever since.

I would recommend it to anyone.

Jose De Aquino - Sunset Nursery - Siverdale NSW

The ease of waist high working afforded by the Comet potting machine means that a days work was completed without bending stress

Berkie Palms - Belmont NSW

More time is now available for stock and nursery maintenance, potting schedules are more achievable resulting in greater efficiency and cost savings.

The benefits to our small nursery have returned dividends more than providing for the lease commitments of the Comet Potting Machine.

Worker compliance is excellent with insistence that all potting chores be completed with the Comet Potting Machine and the consistency of pot fill packing is easily repeatable.

Berkie Palms - Belmont NSW

We looked all around Australia and found the Comet Potting Machine to be the Rolls Royce of Potting Machines. It is very quiet and easy to use - anyone can operate it.

We used to do with the old machine, 1,000 a day, with the Comet we now do 900 per hour with ease

Wayne Parr - The Citrus Nursery - Torbanlea QLD

The Comet has taken the place of two people in our nursery. I am not so tired these days when potting and when I have finished I am looking for more.

Nick and I are potting up at least three times more these days. We are happy with the machine and do recommend it to everyone.

Nick and Inika Kroh - Lindloj Nursery - Oakdale NSW

All I can say is that now we have had your potting machine in operation for 11 months, that it has surpassed all our expectation.As you are aware, we evaluated it's performance for 18 months before finally making the purchase and our confidence in your machine has really paid off.

It has increased production, released staff into other areas of the nursery, lessened physical stress on staff and enabled us to increase productive nursery area without corresponding increase in staff.

We are wholly delighted with it's trouble free performance and if and when we require another machine we will be definitely coming to see you. Thanks

Leverett Wholesale Nurserymen - VIC

*[Owner]* An industrial laundry system service company needed repairs and redesign done to their tooling. C-Mac made changes to the tooling to make access and ease of use to decrease service down times.

*[Service Manager]* An industrial fan service company had a failure of a major shopping centre air conditioning fan/ blower. C-Mac repaired the unit within a 24hr turn around for minimum downtime.

*[Owner/Manager]* A major food manufacturer specializing in tomato sauce had a filling machine breakdown. The machine was brought to C-Mac and repaired in 24hrs for minimum downtime of the production line costing $5,000 per hour.

*[RAAF - Warrant Officer]* Airfield support staff required a portable sandbagging frame and requested a design, prototype and trials at no cost. There was nothing suitable on the market i.e. made in Australia. "Sandbagging Frames":materials-handling/1-bagging-equipment#silt-bagging-frame are now on the national procurement data base and some probably overseas at different war zones.

*[Mechanical Design Engineer]* An automotive transmission design customer needed help with designing an automatic transmission gear prototype. We suggested and engineered a more cost effective and practical way for the mass production stage.

*[Nursery Manager]* At an exhibition saw our self tracking nursery trailers and indicated he had a costly issue transporting large (heavy) pots containing advanced trees. Existing method was a bobcat. C-Mac designed and quoted for the manufacture of a Self Tracking “Low Loader”. His comment on the first day of using "Low Loader trailer":nursery-equipment/7-trailers/#low-loader-self-tracking-trailer “Can now move 100 litre pots with trees, 150 metres in 1 hr and not get a sore back”.

*[Purchasing Officer]* A mining design and machining company needed help with machining components urgently as they were too busy to keep up with the demand. C-Mac machined the components so the deadline could be met.

*[General Manager]* Customer had to submit a proposal and compete against other countries for the manufacturing facility. C-Mac submitted drawings to show there was space in existing plant to install the new process and to comply with all Australian OH&S Standards. Working together with customer to submit proposal to the Head Office overseas WON the contract. Project was a success meeting 6month lead time and budget.

*[Nursery Owner]* Needed a specific Potting & Mixing machine. for his yuccas nursery, but the problem was it was no longer manufactured. From his description and specifications our engineers designed and modelled in 3D software his requirements. "Potting Machine":nursery-equipment/3-potting-machines/ was manufactured and fully tested with potting media in our workshop, video was then sent to customer who was very pleased with the results. Machine disassembled and freighted interstate and installed.

*[Maintenance Engineer]* An industrial hydraulic fitting manufacturer had problems with gear and shaft breakages with their machinery. They also had problems repairing and maintaining. C-Mac offered to repair and maintain their machinery on-site instead of having to permanently employ fitters.

21/64 Drummond St

South Windsor NSW 2756

Phone: (02) 9631 6000