Growing vegetables and flowers or trees during the summer months in Australia has always been difficult. This is due to high temperatures, high water needs of the plants, weeds, insects, diseases and sometimes long periods of rain.

Shade house - The ultimate solution

With a quality shade house in place, regardless it is small or large, there are so many benefits associated with it (See below). It is a valuable asset to have when it comes to growing plants and protecting them properly.

Normally a propogated plant would be moved out from a igloo or glass house production area to an area with 70 or 80% shade, then after a period of time it would be moved to an area with 30% shade and thereafter into the full sun.

What is a shade house?

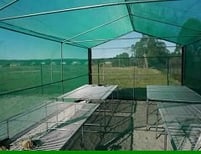

What is a shade house?A shade house is for maximum growing of indoor, shade loving plants (as opposed to full sun in a greenhouse/Glasshouse/Hot House) as well as for raising seedlings.

A shade house is a structure which usually consists of a metal frame that supports shade cloth - a type of screen that provides some passive environmental control e.g. shading the plants from excessive sunlight and wind.

In warmer climates shade houses are useful for growing a range of plants that grow well in cool to temperate regions but do not cope with the amount of hot direct sun. In a cold snap, more elaborate shade houses can be heated to prevent frost damage to the plants.

Research has proven that optimal shading conditions effect significantly the growth aspect for many species of plants.

Fruits and vegetables: eg. tomatoes

Fruits and vegetables: eg. tomatoesA shade house is important in plant production for gaining maximum growth, allowing plants time to acclimatize to outdoor conditions and "harden off". There are a number of benefits in using a shade house:

Protection

Protection Increase yields and quality. The result of a healthier root system

Increase yields and quality. The result of a healthier root system High Quality

High Quality

Flexible

Shade House Kits available in gable roof, flat roof and Lean-to.

Shade House Kits available in gable roof, flat roof and Lean-to. )

)Spare Parts Availability

Great Support

Tube Frame

Tube Frame Eyelets are used to attach shade cloth to structure using cable ties

Eyelets are used to attach shade cloth to structure using cable tiesSeparate sections provide for easy replacement if shade cloth should be damaged at any time, without the expense of having to replace the complete shade house cloth cover.

Shade house coverings are made in 3.2m wide sections (not a single piece cover) for easy assembly and replacement.

Shade house coverings are made in 3.2m wide sections (not a single piece cover) for easy assembly and replacement.

When it comes to replace or update “shadecloth” on your existing shade houses, shade cloth can be purchased from C-Mac. The replacement shade cloth will be tailored to your sepcific dimensions.

Standard lockable hinged door located centrally on end wall

Standard lockable hinged door located centrally on end wallReplacement parts

The video was originally produced by our customer Charlotte Webb from Southern Highlands Botanic Gardens in Bowral. The BIG Shade house construction is done by their volunteers.

"I cannot speak highly enough of Suzi, Aaron and the team at C-Mac Industries. They pulled out all the stops to fill our order for a shade house and benching at the Southern Highlands Botanic Gardens. They readily understood our special needs as a garden still in the early stages of development.

"I cannot speak highly enough of Suzi, Aaron and the team at C-Mac Industries. They pulled out all the stops to fill our order for a shade house and benching at the Southern Highlands Botanic Gardens. They readily understood our special needs as a garden still in the early stages of development.

The products are of the highest quality and were supplied in kit form with easy-to-understand instructions. Our team of volunteers soon proved that the shade house and benches were indeed easy to install. C-Mac Industries ticked all the boxes"

----- Charlotte Webb from Southern Highlands Botanic Gardens in Bowral NSW 2576

"My C-Mac shade house has made looking after the many different orchids in my collection much easier. The benches are a good width and height and the various parts of the shade house fitted together well and the completed structure feels solid."

"My C-Mac shade house has made looking after the many different orchids in my collection much easier. The benches are a good width and height and the various parts of the shade house fitted together well and the completed structure feels solid."

----- Barbara Simcock (Orchid Hobbyist at Kurrajong)

(Barbara is the proud owner of a newly assembled CMAC “Spring Shade House” with 3 Tier “Spring Benching” in her back yard)

*Please Note:

Spring Benches are free standing in shade house (not attached) and are designed to fit into a Spring Shade House.

Extras that you can put in your shade house to make it work better for your plants (eg. orchids) - see image on the right

Extras that you can put in your shade house to make it work better for your plants (eg. orchids) - see image on the right

Would you like to get more information on the specific shade houses we manufacture in Sydney, please visit our Shop.

"Hi Suzi, Thanks very much for organising delivery of the shadehouse. It arrived on 2 October 2018 as requested and I now have it up with the help of my wife and in use. I am impressed with the "quality and finish" of the components and how good the completed house looks. I am very pleased with my choice. I should also add that I found the amateur video linked to your website very helpful." ---- Bill

*Please note:

WE ARE CURRENTLY UPGRADING OUR SHADEHOUSE MACHINERY AT OUR SYDNEY FACTORY SO 8 WEEK LEADTIME CURRENTLY APPLIES. WE EXPECT TO BE ABLE TO SUPPLY EX STOCK WITH A STANDARD 1 WEEK DELIVERY BY APRIL 2021.

Woud like to get a quality shade house despatched to you ASAP?

Other nursery equipment such as Shade house benching, and Trailers, which also reduce risk of getting injury and increase work efficiency are also available.

C-Mac's Spring Shade houses are extremely popular Australian wide, so we are looking for some regional Shade houses resellers to partner up. Click here to see the contact details

*[Owner]* An industrial laundry system service company needed repairs and redesign done to their tooling. C-Mac made changes to the tooling to make access and ease of use to decrease service down times.

*[Service Manager]* An industrial fan service company had a failure of a major shopping centre air conditioning fan/ blower. C-Mac repaired the unit within a 24hr turn around for minimum downtime.

*[Owner/Manager]* A major food manufacturer specializing in tomato sauce had a filling machine breakdown. The machine was brought to C-Mac and repaired in 24hrs for minimum downtime of the production line costing $5,000 per hour.

*[RAAF - Warrant Officer]* Airfield support staff required a portable sandbagging frame and requested a design, prototype and trials at no cost. There was nothing suitable on the market i.e. made in Australia. "Sandbagging Frames":materials-handling/1-bagging-equipment#silt-bagging-frame are now on the national procurement data base and some probably overseas at different war zones.

*[Mechanical Design Engineer]* An automotive transmission design customer needed help with designing an automatic transmission gear prototype. We suggested and engineered a more cost effective and practical way for the mass production stage.

*[Nursery Manager]* At an exhibition saw our self tracking nursery trailers and indicated he had a costly issue transporting large (heavy) pots containing advanced trees. Existing method was a bobcat. C-Mac designed and quoted for the manufacture of a Self Tracking “Low Loader”. His comment on the first day of using "Low Loader trailer":nursery-equipment/7-trailers/#low-loader-self-tracking-trailer “Can now move 100 litre pots with trees, 150 metres in 1 hr and not get a sore back”.

*[Purchasing Officer]* A mining design and machining company needed help with machining components urgently as they were too busy to keep up with the demand. C-Mac machined the components so the deadline could be met.

*[General Manager]* Customer had to submit a proposal and compete against other countries for the manufacturing facility. C-Mac submitted drawings to show there was space in existing plant to install the new process and to comply with all Australian OH&S Standards. Working together with customer to submit proposal to the Head Office overseas WON the contract. Project was a success meeting 6month lead time and budget.

*[Nursery Owner]* Needed a specific Potting & Mixing machine. for his yuccas nursery, but the problem was it was no longer manufactured. From his description and specifications our engineers designed and modelled in 3D software his requirements. "Potting Machine":nursery-equipment/3-potting-machines/ was manufactured and fully tested with potting media in our workshop, video was then sent to customer who was very pleased with the results. Machine disassembled and freighted interstate and installed.

*[Maintenance Engineer]* An industrial hydraulic fitting manufacturer had problems with gear and shaft breakages with their machinery. They also had problems repairing and maintaining. C-Mac offered to repair and maintain their machinery on-site instead of having to permanently employ fitters.

21/64 Drummond St

South Windsor NSW 2756

Phone: (02) 9631 6000