C-Mac provides clients with QUALITY & FAST 3d Printing Service in Sydney Australia with COMPETITIVE PRICE.

C-Mac provides clients with QUALITY & FAST 3d Printing Service in Sydney Australia with COMPETITIVE PRICE.3d printing (additive manufacturing) is the opposite of CNC Machining and Milling (known as “subtractive manufacturing”). 3d printing is a process to rapid prototype a 3 dimensional solid object from a digital file. 3d models/objects are created by depositing materials layer by layer that eventually forms a pre-designed shape.

The traditional manufacturing method of conventionally machining prototypes tends to be slow where more materials are generally used, especially when it comes to producing complex (functional) shapes.

3d printing enables designers and engineers to create prototypes faster and cheaper before reaching the stage of massive production. Hence, risks can be greatly reduced.

The current trend in 3d printing industry is that there is an increasing numbers of companies start to utilise 3d design and 3d printing to make their final products because the advanced 3d printers can now work with a wider range of materials.

With 3d printing, desired objects can be easily made which requires minimum assembly and customisation of a part is a lot easier than before. However, it can't be achieved without 3d printers.

For 3d printing DIYers, one thing have to keep in mind is the huge cost of the 3d printers as well as the time spent on researching and buy the right one. Remember you get what you pay for!

Another reason to get a local 3d printing service provider is to avoid costly 3d printing mistakes, just leave the hard work and technical stuff to the professionals, resting assured that the products/samples can be 3d printed accurately in shape and using the right materials and proper technology.

Need more in-depth knowledge in 3d printing?

Before outsourcing your 3d printing service to a local vendor in Australia, it is very crucial to understand 3d printing thoroughly and understand what exactly you have been looking for. Below are a few questions that can help.

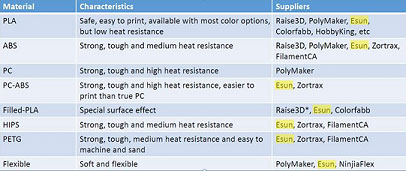

Different materials should be used to 3d print different components which are used for different purposes. For example, sometime meta 3d printing is not the right choice and plastic 3d printing is better (see story in testimonial below)

Different 3d printing service providers use various 3d printers to cater for different sizes of parts, so do make sure they are capable of doing the job well.

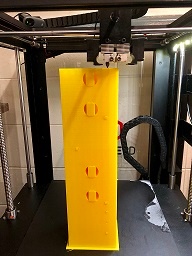

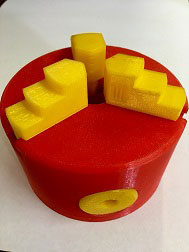

When it comes to industrial 3d printing, yellow and red are the popular colors as they stand for safety which minimise risk at workplace, but the vendor should be able to do the printing using a variety of colours.

Usually different 3d printing suppliers can produce custom 3d printed parts for you but with different accuracy and quality. Always look for the one that can exceed your expectation.

When it comes to industrial 3d printing, yellow and read are the popular colors as they stand for safety which minimise risk at workplace.

Everything comes down to cost/price. It is the same for 3d printing. Basically build time, setup and labour time affect the total service fee. For example if a 3d design/drawing is ready for use and printing, the cost is less than with NO part CAD model available or have design errors that needs to be amended.

1. 3d model and product design by our in-house Sydney based mechanical designers and draftsmen who have years of experience and qualifications.

2. Adopting the latest cutting edge technology and using our advanced 3d printers in Sydney, custom 3d printing your products/parts/samples/models with high volume run capability.

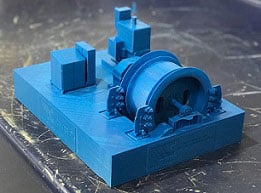

(1) This is a memento of a large cable winder, for a retiring worker that used to repair them. Printed size is 300mm X 300mm. 100 hours of printing in each unit.

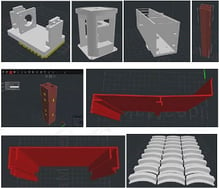

(2) This customer made fine hand made chocolates. They needed a chocolate mould manufactured overseas which was going to be very costly, and wanted to see what the component would look like physically before they ordered the expensive mould. The mould supplier emailed the drawing exported in .stl format to C-Mac who then 3D printed the finished component and our customer was then able to to see what the chocolate mould would produce before committing to its purchase.

(3) This customer who is an artist asked C-Mac for assisntance of 3d printing an Opera House, so he could paint and frame it. He had his work projected on the Opera House at Vivid this year.

Contact C-Mac on (02) 9631 6000 to make an inquiry or

For General public

Contact C-Mac on (02) 9631 6000 to make an inquiry or

The 3d Printing Machines being used to provide the service are fully enclosed and located in an air-conditioned room at C-Mac. With wifi connection and remote video monitoring, products can be made 24 hours per day.

3D Printing is highly reliable generally with no need to start the production run for reworks, even if there is an electrical power blackout.

The 3D Printing Dual Colour Plastic Extruder with twin nozzles has the capability of 10 micron accuracy producing products in various colours and types of plastic materials. Large build volumes are possible.

Specification:

"I must say I have been converted to and amazed by this 3D printing. With a small prototype design project the 3D printing enabled fast customised and most importantly a very cost effective solution. I chose to engage C-Mac originally because of their experience with metal work and ability to provide design solutions; though in the end it was all plastic and exceeded my expectations. The team at C-Mac suggested we use 3D printing and at first I was unsure - plastic, easier, strong...were all my questions.When I picked up the finished design, it delivered. I would definitely encourage someone for 3D printing for early design testing and the C-Mac team did an excellent job! Thank you!" --- By Richard

"Thank you so much for producing the RTD concept bottles, we are extremely happy with how they have turned out and look forward to working on other projects with you. Based on what you have supplied us we would like to expand our portfolio to include 3D printed samples to our customers and would be very interested in working with you and your team" --- Jessica, Sales Co-Ordinator/Project Manager

Contact C-Mac on (02) 9631 6000 to make an inquiry or

Simply send in your 3d drawing file in .stl or .obj format and make an inquiry by clicking on the yellow button below.

If you don’t have a 3d model drawing file, our draftsmen at C-Mac can generate this for you at our standard hourly rate. 3D Printing opens up many possibilities in design of products and prototypes.

*[Owner]* An industrial laundry system service company needed repairs and redesign done to their tooling. C-Mac made changes to the tooling to make access and ease of use to decrease service down times.

*[Service Manager]* An industrial fan service company had a failure of a major shopping centre air conditioning fan/ blower. C-Mac repaired the unit within a 24hr turn around for minimum downtime.

*[Owner/Manager]* A major food manufacturer specializing in tomato sauce had a filling machine breakdown. The machine was brought to C-Mac and repaired in 24hrs for minimum downtime of the production line costing $5,000 per hour.

*[RAAF - Warrant Officer]* Airfield support staff required a portable sandbagging frame and requested a design, prototype and trials at no cost. There was nothing suitable on the market i.e. made in Australia. "Sandbagging Frames":materials-handling/1-bagging-equipment#silt-bagging-frame are now on the national procurement data base and some probably overseas at different war zones.

*[Mechanical Design Engineer]* An automotive transmission design customer needed help with designing an automatic transmission gear prototype. We suggested and engineered a more cost effective and practical way for the mass production stage.

*[Nursery Manager]* At an exhibition saw our self tracking nursery trailers and indicated he had a costly issue transporting large (heavy) pots containing advanced trees. Existing method was a bobcat. C-Mac designed and quoted for the manufacture of a Self Tracking “Low Loader”. His comment on the first day of using "Low Loader trailer":nursery-equipment/7-trailers/#low-loader-self-tracking-trailer “Can now move 100 litre pots with trees, 150 metres in 1 hr and not get a sore back”.

*[Purchasing Officer]* A mining design and machining company needed help with machining components urgently as they were too busy to keep up with the demand. C-Mac machined the components so the deadline could be met.

*[General Manager]* Customer had to submit a proposal and compete against other countries for the manufacturing facility. C-Mac submitted drawings to show there was space in existing plant to install the new process and to comply with all Australian OH&S Standards. Working together with customer to submit proposal to the Head Office overseas WON the contract. Project was a success meeting 6month lead time and budget.

*[Nursery Owner]* Needed a specific Potting & Mixing machine. for his yuccas nursery, but the problem was it was no longer manufactured. From his description and specifications our engineers designed and modelled in 3D software his requirements. "Potting Machine":nursery-equipment/3-potting-machines/ was manufactured and fully tested with potting media in our workshop, video was then sent to customer who was very pleased with the results. Machine disassembled and freighted interstate and installed.

*[Maintenance Engineer]* An industrial hydraulic fitting manufacturer had problems with gear and shaft breakages with their machinery. They also had problems repairing and maintaining. C-Mac offered to repair and maintain their machinery on-site instead of having to permanently employ fitters.

21/64 Drummond St

South Windsor NSW 2756

Phone: (02) 9631 6000