Amongst Australian manufacturing, sectors such as fabrication, engineering and other similar manufacturing businesses, industrial noise is a huge issue that has raised a lot of concern.

You may know that excessive industrial noise harms blue collar workers in factories, but do you really understand industrial noise and its impact? Do you know that you might lose hundreds of thousands of dollars when it comes to dealing with industrial noise related accidents and hearing loss claims?

Let’s take a look at the definition of Industrial Noise first.

Definition from Wikipedia: Industrial noise is often a term used in relation to environmental health and safety, rather than being a nuisance, as sustained exposure can cause permanent hearing damage.

The Harm that Industrial Noise Causes

According to "Noise in Workplace" the document developed by Safework South Australia, eight-hour exposure of 85 dB(A) is considered to represent an acceptable level of risk to hearing health in the workplace while Impulse noise levels in excess of the peak exposure standard of 140 dB(C) are considered to be extremely hazardous and painful, capable of causing immediate hearing damage.

If workers are exposed to noise over time, they will suffer from hearing loss. The damage is severe as the hearing loss would prevent them from keeping up or hearing conversations, listening and chattering with other people on the phone could be difficult not understanding every day speech. Apart from hearing loss, people may develop tinnitus (ringing, whistling, buzzing or humming in the ears), which can lead to disturbed sleep. Lack of good sleep usually causes other problems and diseases.

At the same time, excessive industrial noise can cause dangerous situations in the workplace. People regularly identify a hazardous situation from warning sounds and then react accordingly. However, when there is excessive noise, a slow workers’ reaction to a hazardous situation, can potentially result in severe injury or even death in the workshop.

What about the law on noise control in Australia?

By law, you as the employer should:- Take action to reduce the noise exposure

- Provide your employees with personal hearing protection (PPE)

- Make sure the legal limits on noise exposure are not exceeded

- Maintain and ensure the use of equipment you provide is within acceptable noise control parameters

- Provide your employees with information, instruction and training

- Carry out health surveillance (monitor workers’ hearing ability)

How do you avoid the big loss from a hearing loss claim?

According to WorkSafe, under S98E No disadvantage compensation table, a worker is entitled to compensation of $177,890 (indexed annually) for a total loss of hearing!

The best way to avoid the big loss from a hearing loss workers compensation claim is to make sure there is no noise in the workplace. Proactive action is always better then reactive. Pre-employment hearing tests are crucial so your company is only responsible for hearing loss from the date of employment.

Therefore, maintaining acceptable noise levels and trying to further reduce the industrial noise in the factory will reduce the likelihood of further hearing loss by your staff. It is not uncommon for staff when they retire to get a hearing test and claim for any loss of hearing, so providing your workers with hearing protection is very crucial to reduce your liability to workers compensation claims.

How to conduct Industrial Noise Control?

There are three elements that contribute to a noise problem: a noise source, a path that propagates the noise, and a receiver of noise. If anyone of these three elements doesn’t exist, there would be no noise. Hence, we can utilise this principle and find the solutions to controlling industrial noise.

To treat the source, a noise source such as a rough-running generator, compressor, exhaust fan or vibrator could be made quieter by tuning it up. To treat the sound path, a barrier or a door could be placed between the generator and the receiver, which will stop the noise from propagating to the receiver. Lastly, the receiver, that is the human’ ear could be treated with enclosures and ear plugs/headset (treating the receiver).

Source Control

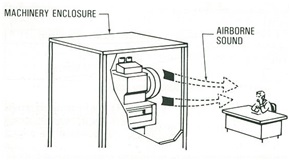

When your project is in the planning stage and you haven’t purchased your machinery yet, it is best to do good research and purchase an innovative machine that generates less noise. If you already have machines operating in-house, the best way is using acoustic products to treat the source. Acoustic products such as enclosure, louvers, silencers and attenuators could be used as to decrease the noise strength at the source. These acoustic products can eliminate the noise problem or control the problem to a certain degree.

When your project is in the planning stage and you haven’t purchased your machinery yet, it is best to do good research and purchase an innovative machine that generates less noise. If you already have machines operating in-house, the best way is using acoustic products to treat the source. Acoustic products such as enclosure, louvers, silencers and attenuators could be used as to decrease the noise strength at the source. These acoustic products can eliminate the noise problem or control the problem to a certain degree.

Path Control

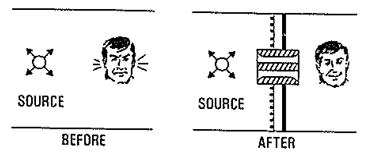

When noise can easily reach the receiver, the impact of noise on the receiver could be huge. But when there is a disruption between the source and the receiver, things are different. Acoustic products such as acoustic barriers and doors can be used to treat the sound path. After having the treatment in place, the amount of acoustical energy would be greatly reduced and only part of the industrial noise can reach the receiver.

When noise can easily reach the receiver, the impact of noise on the receiver could be huge. But when there is a disruption between the source and the receiver, things are different. Acoustic products such as acoustic barriers and doors can be used to treat the sound path. After having the treatment in place, the amount of acoustical energy would be greatly reduced and only part of the industrial noise can reach the receiver.

Receive Control

Acoustic Room and Ear plugs/Headset are usually used to treat the receiver. Although ear plugs/ear muffs are more economic than an acoustic enclosure or an acoustic room, workers usually are not comfortable or are reluctant to wearing PPE for a long time and there is reluctance due to the inconvenience of communication. When a worker is wearing his ear plugs, it is hard for them to hear equipment entering their work space, which might cause danger and injury. Therefore, to decrease the noise level that reaches the receiver, a personnel enclosure is by far the better option.

Conclusion

Industrial noise control is very important topic in the manufacturing sector. Excessive industrial noise has a great negative impact on the workers and the environment and will cause not only hearing loss and disease to staff, but the potential of a huge amount of compensation on a hearing loss claim can be suddenly a great burden for any employer.

Therefore, stay proactive! When you need to raise your voice to communicate with somebody standing 1-2 meters always from you in your factory, you might have come across a noise problem.

Don’t hesitate to have an acoustic consultant evaluate the problem and make recommendations. A simple proactive action will avoid you from paying hundreds or thousands of dollars for a worker’s compensation hearing loss claim when a noise-caused accident happens.

(Please share this article by clicking the social icons below if you think it is valuable to other people)

PS. You can click here for Acoustic Products Case Study